Instructions for use of GM328A transistor tester

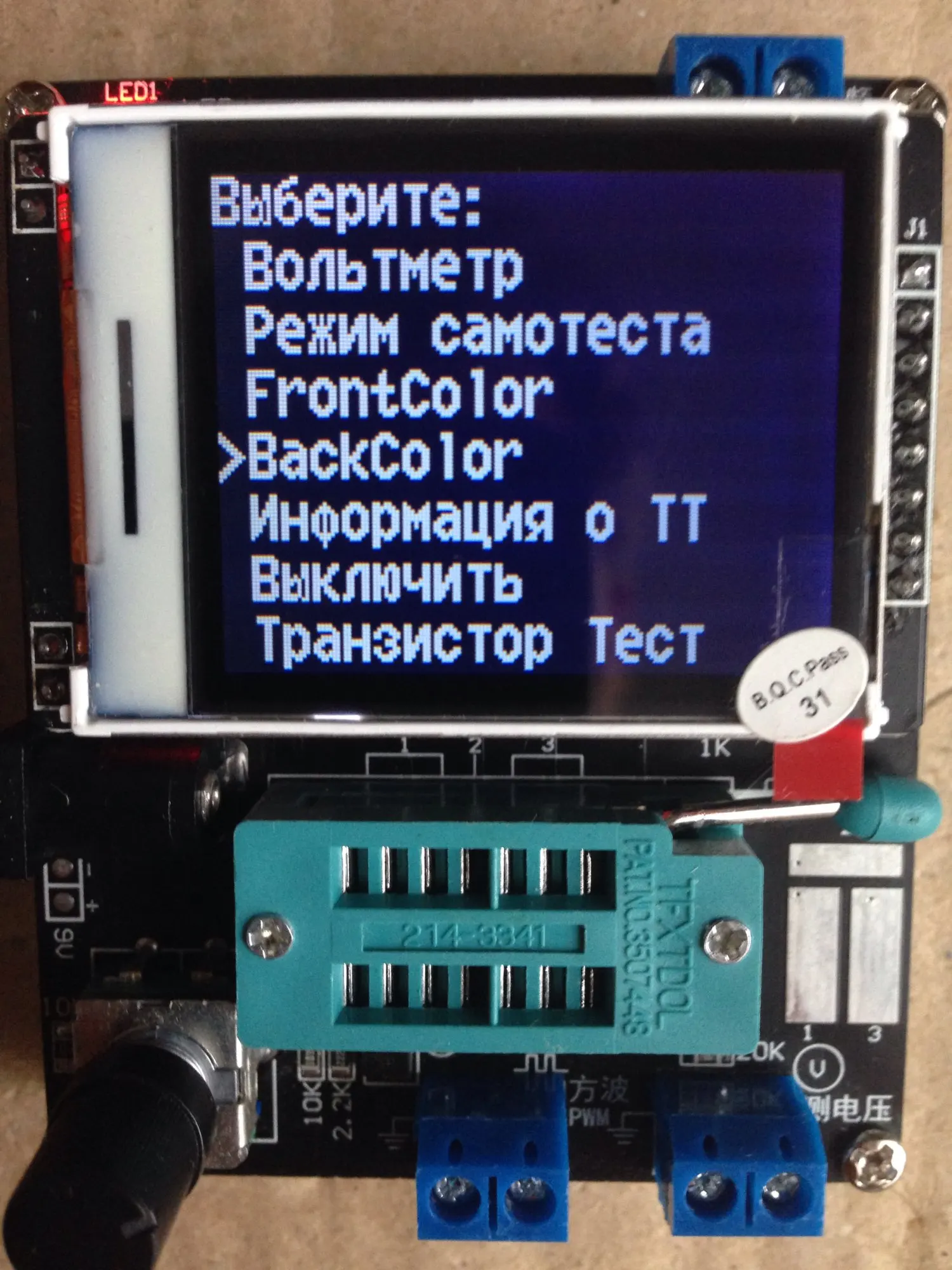

Note:The following functions are all available in English version, some functions are not updated in Russian version

Description:

Input voltage: DC 6.8V-12V

Working voltage: about 30mA, measured when inputting 7.5V DC voltage

Transistor tester control

The tester is controlled by a rotary encoder switch,

The rotary encoder switch can have a total of 6 operations, short press, long press, left rotation, right rotation, hold left rotation, hold right rotation.

In the shutdown state, short press once to turn on the power and start the test.

After a test is completed, if the device is not detected. Long press the switch or the left and right rotary switch to enter the function menu. After entering the function menu, the left or right rotary switch can be selected up and down in the menu item. To enter a function item, short press the switch once. When you need to exit from a function, press and hold the switch.

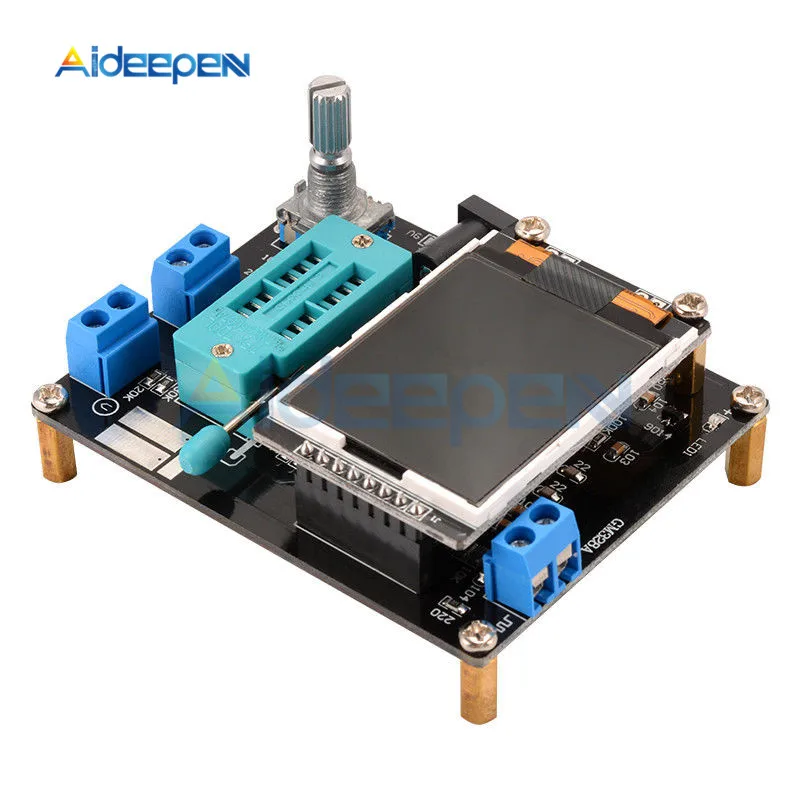

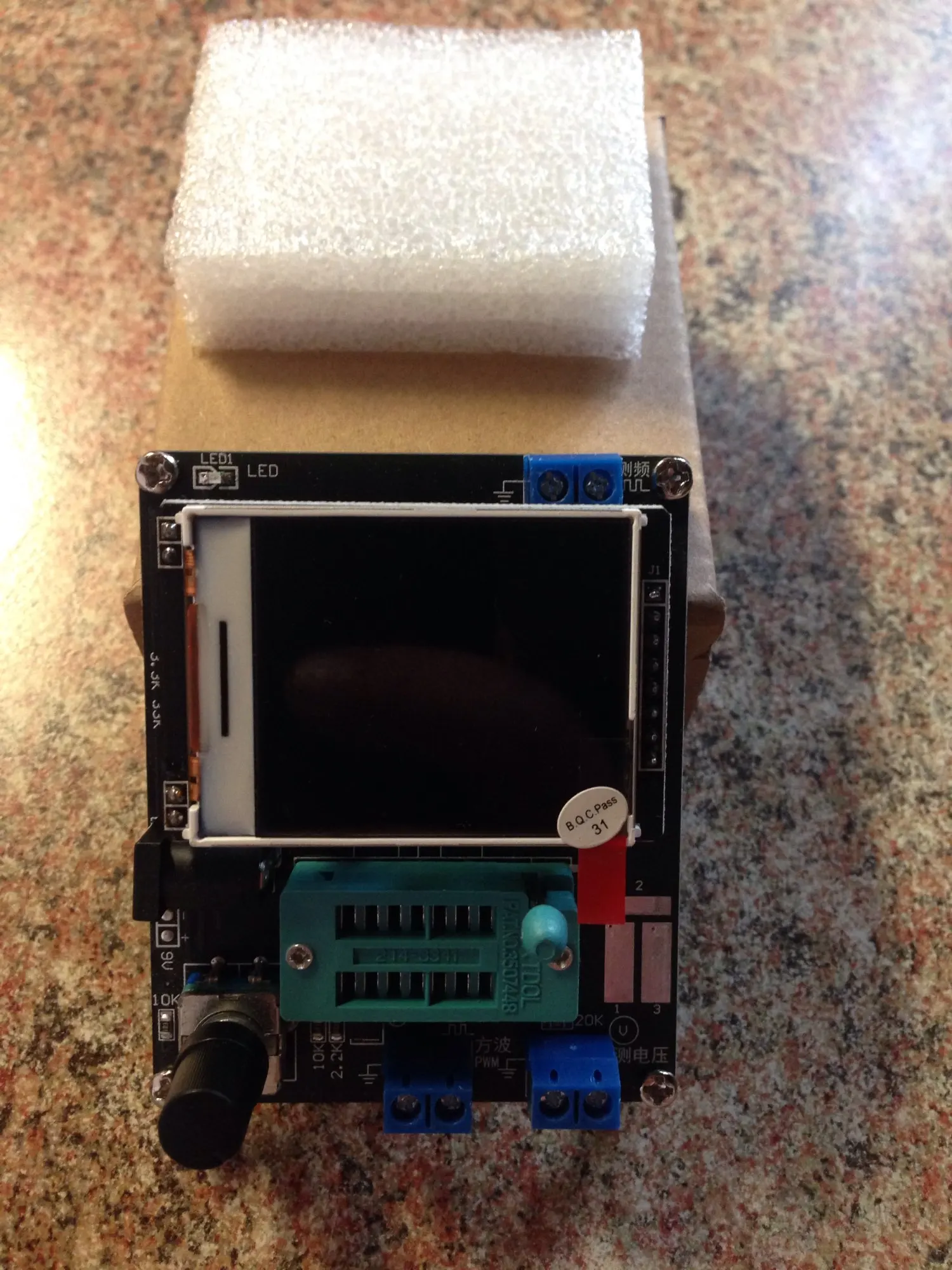

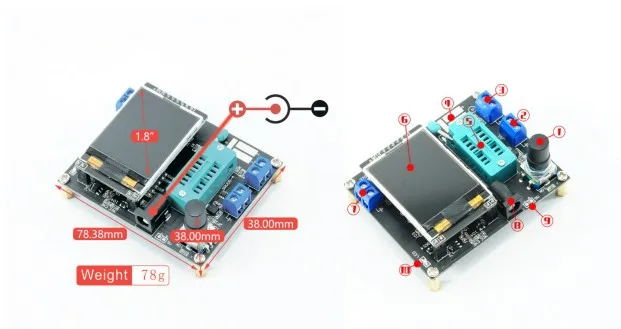

①Control button

②Square wave and PWM outputinterface

③voltage measurement interface

④Original test bit

⑤In the original test base

⑥160×128 full color display

⑦Frequency messurement interface

⑧Power adapter socket

⑨9V battery contact 9V

⑩Work indicator

Version function comparison

Features

English

Russian

Switch off

Yes

Transistor

Yes

f-Generator

Yes

10-bit PWM

Yes

:3

:3

Yes

C+ESR@TP1:3

Yes

1-||-3

Yes

DS18B20

Yes

No

C(uF)-correction

Yes

IR_Decoder

Yes

No

IR_Encoder

Yes

No

DHT11

Yes

No

SelfTest

Yes

Voltage

Yes

FrontColor

Yes

No

BackColor

Yes

No

Show data

Yes

Test device

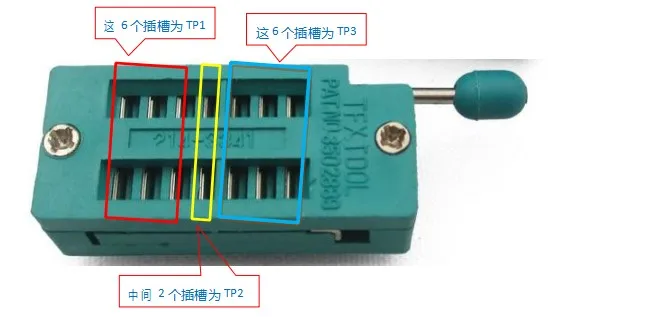

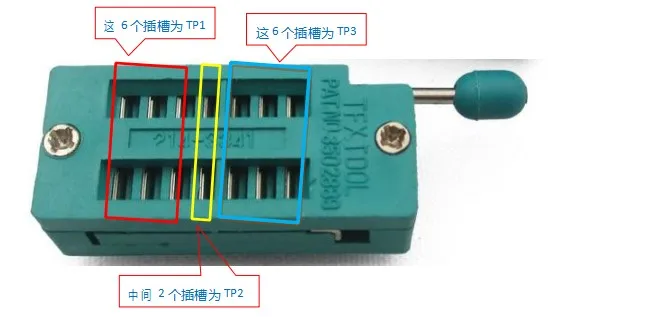

The tester has 3 test points, TP1, TP2, TP3. The distribution of these three test points in the test block is as follows:

On the right side of the test seat is the test position of the patch component, there are numbers 1, 2, and 3 respectively, each representing TP1, TP2, and TP3

When testing a component with only 2 pins, the pins are not divided into the test order, 2 pins are arbitrarily selected for 2 test points, and the device pins with 3 pins are placed in three test points respectively, regardless of the order. After the test, the tester automatically recognizes the pin name and test point of the component, and displays it on the screen.

When testing a component with only 2 pins, if two test points TP1 and TP3 are used, it will automatically enter the continuous test mode after the test is completed, so that the components on TP1 and TP3 can be continuously and synchronously measured without pressing the switch. If you are using the "TP1 and TP2" or "TP2 and TP3" test, only test once. To test again, press the switch once.

Before testing the capacitor, discharge the capacitor first, and then insert the test socket for measurement, otherwise the single-chip microcomputer of the tester may be damaged.

1. Calibration

The tester calibration is used to eliminate the errors of its own components and make the final test results more accurate. Calibration is divided into quick calibration and full-function calibration.

The operation method of quick calibration: short-circuit the three test points TP1, TP2, and TP3 with wires, then press the test button while observing the screen. The color of the screen will change to black and white. After the prompt message "Selftest mode..?" appears, press the test button to enter the quick calibration process; if the prompt message "Selftest mode..?" appears, 2 seconds If there is no button in the clock, a normal test process is performed, and finally the resistance value of the three test points of TP1, TP2 and TP3 is displayed. After entering the quick calibration process, some data will appear on the screen, just ignore it. Wait until a flashing string appears on the screen

After "isolate Probes!", remove the wires that short-circuit TP1, TP2, and TP3. After the character string "Test End" appears on the screen, the quick calibration is completed. When calibrating for the first time, use the full-function calibration method.

Full function calibration needs to be entered from the function menu, and a 220nf capacitor is also required. The full-function calibration performs a more comprehensive calibration process and will take longer. After entering the function menu, rotate the test button to the menu item "Selftest", and then press the test button to enter the full-function calibration process. The flashing string "short Probes!" appears on the screen, which is the same as the quick calibration. Use wires to short-circuit the three test points and wait for the calibration process to proceed. When the flashing string "isolate Probes!" appears on the screen, remove the wires that short-circuit the three test points and continue to wait for the calibration process to proceed. When the character string "1-||-3> 100nf" is output, install the prepared 220nf capacitors on the test points TP1 and TP3. Wait until the screen prompts "Test End", the full-function calibration process is complete.

2. Function menu

2.1 Switch off

2.2 Transistor

2.3 Frequency

Measuring frequency. Long press the test button to exit the frequency measurement function. The frequency measurement range is from 1Hz to above 1MHz. When the measured frequency is lower than 25KHz, the period is displayed

2.4 f-Generator

Square wave generator, there are multiple square wave frequencies to choose from, left or right rotation test button to switch different square wave frequencies, long press the test button to exit the square wave generator.

2.5 10-bit PWM

Pulse signal generator, rotate the test button left or right to adjust the duty cycle of the pulse, from 1%-99%. Long press the test button to exit the pulse signal generator.

2.6 C+ESR@TP1:3

Capacitance online measurement function, two wires can be drawn from TP1 and TP3, and the capacitance value and ESR of 2uF-50mF capacitors can be measured online. Note that the measured capacitance must be completely discharged before the test. If it is online measurement, the circuit where the capacitance is located must be completely disconnected It can only be carried out after electricity.

2.7

The continuous resistance measurement method continuously tests the resistance and inductance values installed on TP1 and TP3. The inductance of the measured resistance is less than 2100 ohms, and the inductance measurement range is 0.01mH-20H. Long press the test button to exit.

2.8 1-||-3

Capacitance continuous measurement method continuously tests the capacitance value installed on TP1 and TP3. For small-capacity capacitors, only this method can be used to measure the capacitance value. Measure the equivalent series resistance (ESR) of capacitors larger than 90nF, and the resolution of ESR is 0.01Ω. Capacitors above 5000pF show the rate of voltage drop after charging.

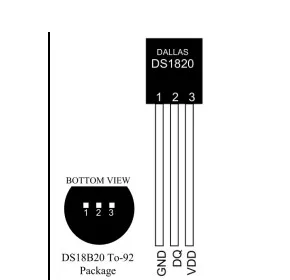

2.9 DS18B20Russian version does not have this function

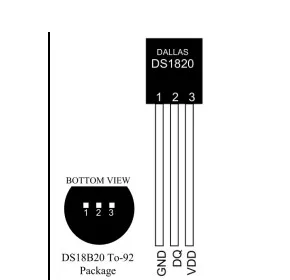

DS18B20 is a temperature sensor that uses single-bus communication to transmit data. It has the same package (TO-92) as a triode. The figure below shows the pin distribution of DS18B20.

After entering the DS18B20 test function, the second line of the display shows the connection relationship between the test socket and DS18B20, "1=GND 2=DQ 3=VDD", which means TP1 is connected to DS18B20 GND, TP2 is connected to DS18B20 DQ, and TP3 is connected to DS18B20 VDD . The tester cannot automatically recognize DS18B20, so you must follow the instructions on the second line to install

Install DS18B20. The tester can read the 12-digit temperature results measured by DS18B20, and display the corresponding temperature in Celsius on the third line with a resolution of 0.0625°C.

Scratchpad: The contents of the 8 storage units inside the DS18B20 read by the tester plus the CRC check value of the last byte. A total of 9 bytes.

Scratchpad BYTE

TEMPERATURE LSB

0

TEMPERATURE MSB

1

TH/USER BYTE 1

2

TL/USER BYTE 2

3

CONFIG

4

RESERVED

5

RESERVED

6

RESERVED

7

CRC

8

For example, the value read once is Scratchpad: EC014B467FFF0C102A has the following relationship:

Scratchpad Value BYTE

TEMPERATURE LSB

EC

0

TEMPERATURE MSB

01

1

TH/USER BYTE 1

4B

2

TL/USER BYTE 2

46

3

CONFIG

7F

4

RESERVED

FF

5

RESERVED

0C

6

RESERVED

10

7

CRC

2A

8

64-bit ROM: The globally unique device ID of each DS18B20 read by the tester. The ID has a length of 64 bits. Divided into 3 parts.

For example, the 64-bit ROM read by a DS18B20 is

64-bit ROM: 28FF4D58361604A1

Then there is

8-BIT FAMILY CODE

28

48-BIT SERIAL NUMBER

041636584DFF

8-BIT CRC CODE

A1

Note: Except that the temperature value (TEMP) is in decimal, the rest are in hexadecimal.

The temperature measurement range of DS18B20 is -55℃-125℃. Long press the test button to exit this function.

2.10 C(uF)-correction

This function is used to correct the measured value of large-capacity capacitors. The default value is 0%. That is, there is no correction, the setting range is -0.2%-8%, when it is a positive value, it will reduce the measured value of the capacitance, and when it is a negative value, it will increase the measured value of the capacitance.

After setting, long press the test button to exit.

2.11 IR_DecoderRussian version does not have this function

Infrared remote control decoding function. This function requires a 1838 integrated infrared receiver (pulse type). After entering this function, observe the prompt on the display screen. The second line will display the character string ""1=DOUT 2=GND 3= VCC", the character string means the connection relation

:3

:3